Product Name: UV+ Evaporation Coating Machine

Product Description: Power-saving high efficiency vacuum coating machine is a vertical double-door evaporation coating machine, which is suitable for metallized decorative film and functional film on the surface of plastic, ceramic, glass, resin, candle and metal materials...

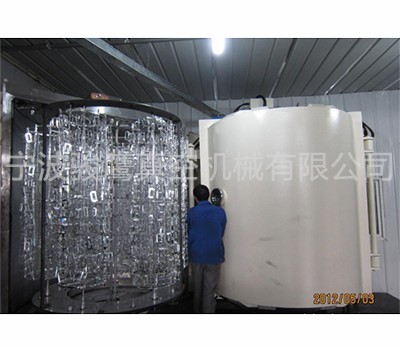

Product Name: UV+ Evaporation Coating Machine

Product Description: Power-saving high efficiency vacuum coating machine is a vertical double-door evaporation coating machine, which is suitable for metallized decorative film and functional film on the surface of plastic, ceramic, glass, resin, candle and metal materials. Adapted to the requirements of the modern coating industry, high efficiency, fully automatic, vacuum technology, evaporation coating and mechatronics technology, is the ideal coating equipment for the preparation of high-grade decorative film. The machine can be widely used in crafts, gifts, hardware appliances, decorations and electronics, machinery, light industry and other industries.

main feature:

Vertical double-opening door structure, equipped with two sets of electromagnetic heating furnace high-power water vapor collector, new evaporating electrode, convenient and quick to install, simple maintenance and repair, the workpiece frame adopts gear-driven public rotation structure, flexible and reliable rotation; vacuum unit configuration Advanced and reasonable, fast pumping speed, high efficiency, energy saving, vacuum control, evaporation coating, etc. All automatic control, the operating system is simple, reliable and beautiful.

basic configuration:

1. Vacuum chamber vertical double-opening door structure, made of 304 stainless steel or carbon steel, effective diameter of vacuum chamber from Φ1800mm to Φ2000mm;

2. The vacuum system consists of a mechanical pump, a rotary vane pump, a Roots pump and a high vacuum oil diffusion pump with a cold trap;

3. The coating system uses two sets of new structure copper electrode resistance evaporation system and power supply;

4. The auxiliary pumping system uses a low temperature water vapor trap;

5. the electronic control system sets the circuit overload, water, air and sound and light alarm device;

6. Control system (touch screen + PLC), display detailed parameters in real time, fully control the entire production process, and automatically store process parameters.